Selective Coating Machine HTF-650B

Features an industrial PC–controlled sealed 3-axis servo platform with automatic nozzle selection, program recall, auto cleaning, independent valves, auto-width conveyor, LED/UV inspection, and strong exhaust, delivering precise, stable, and high-yield conformal-coating performance.

Long-Stroke Selective Coating Machine HTF-650B

Introduction

- Control Section:

Equipped with an industrial computer and motion control card, operated via a 21-inch monitor with mouse and keyboard. Programming is simple and user-friendly. The software is independently developed for easy maintenance. When creating programs, operators can select different spray valves according to required coating width and adjust Z-axis height based on component height on the PCB. All programs can be stored and recalled for different PCB models. The system can automatically immerse the glue gun when no workpiece is present, preventing adhesive drying and clogging. - Frame Section:

The frame is welded with thickened 60×60 square tubes and treated with aging. It is solid, rigid, hard, and resistant to thermal deformation. The working platform is milled flat by a gantry milling machine to ensure stable and accurate motion performance. The areas outside the main frame are covered with stainless steel to prevent corrosion from conformal coating. The surfaces are finished with electrostatic powder coating for a refined appearance. - Working Section:

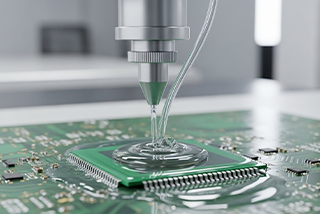

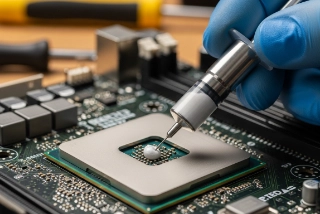

The X/Y/Z motion platform consists of linear guides, ball screws, and servo motors. The XYZ axes use a self-developed sealed slide table to prevent atomized glue from attaching to the screw or guide. This ensures stable and precise motion control. Each glue valve is controlled independently, achieving smooth and high-precision dispensing. The spray guns include dispensing valves and high-precision atomizing spray valves, with adjustable spray width. The atomizing pressure valve adopts a fine-adjust regulator, ensuring stable air pressure and consistent glue output, enabling precise edge cleanliness control. - Conveyor Section:

Driven by a stepper motor. The guide rail includes protective strips to ensure stable transport even when high-viscosity glue adheres to the chain. The self-developed conveyor aluminum profile is convenient and visually appealing. Transmission uses chain drive, with protective strips above the chain to prevent conformal coating from contaminating it. Conveyor width is automatically adjusted via stepper motor, achieving high precision, with an adjustment range of 50–650 mm. The chain is a 35B stainless steel chain with extended pins and baffles. - Clamping Device:

When the PCB enters the coater, a photoelectric sensor triggers board stopping, clamping, and top pressing to firmly fix the PCB, avoiding deviation during coating and improving coating accuracy. - Glue Supply System:

The glue-supply cart consists of a 10 L glue tank and a 2 L stainless steel cleaning tank. The cart includes casters for easy movement. The pressure tank includes an air regulator, safety valve, air release valve, outlet, and inner tank. - Exhaust System:

Uses a top-mounted high-power exhaust fan with strong suction, durability, and quiet operation. Ensures complete extraction of atomized conformal coating particles, preventing them from diffusing into the workshop (not included in standard machine). - Soaking Device:

A custom stainless-steel container with convenient and cleverly designed structure for easy replacement. - Lighting Inspection Section:

Equipped with LED lighting and a built-in LED UV inspection light. A switch allows conversion between modes. The UV source is used to inspect conformal coating coverage on the PCB. - Cleaning Function:

The machine includes automatic cleaning. After shutdown, switching to cleaning mode allows the cleaning liquid in the pressure tank to be pushed through the spray gun, completing automatic cleaning without manual disassembly.

Feature Summary

- SMEMA interface for equipment communication

- Industrial PC + motion control card, Windows operating system, sound-light fault alarm, and menu display

- Manual teaching programming, simple and fast

- Servo motor + ball screw drive

- X/Y/Z three-axis movement

- Operating precision: 0.02 mm, automatic error compensation

- Special aluminum alloy rail and stainless steel conveyor chain, single-section guide rail

- Integrated steel motion platform for stable operation

- Automatic glue-valve cleaning device

Equipment Parameters

| Model:HTP-650B | Rotation Angle: None |

| External Dimensions: 1200×1400×1699(mm) | Tilt Angle: None |

| Body Weight: 700kg | Positioning Accuracy: ±0.02mm |

| Control System: Industrial Computer + Motion Control Card | Repeat Positioning Accuracy: ±0.02mm |

| Operating Software: Hetong Selective Coating | Max Speed (X/Y Axis): 800mm/sec |

| Programming Method: Trajectory diagram available; | Max Speed (Z Axis): 300mm/sec |

| Driving Method: Servo Motor + Ball Screw | X/Y Axis Stroke: 650×650mm |

| Number of Tracks: 1-section Transportation | Y Axis Amplitude Range: 50~650mm |

| Conveying Height: 900±20mm | Amplitude Adjustment: Electric |

| Conveying Speed: 2-5m/min | Adjustment Speed: 250mm/min |

| Conveying Direction: L→R | Max Component Height: 100mm (above/below conveying surface) |

| Chain Type: 35B Stainless Steel Chain (with Blocker & Extended Pin) | PCB Thickness: 0.5~4.0mm |

| Max Transportation Load: 20kg | PCB Edge Space: ≥5mm |

| Conveying Motor Power: 57 Series Stepper Motor | Small Atomization Coating Thickness: 5~200μm |

| Axis Number: X, Y, Z | Small Atomization Coating Width: 5-20mm |

| Z-axis Valve Quantity: 2 pcs | Minimum Dispensing Diameter of Needle Valve: 1.5mm |

| Air Supply:0.4-0.6 Mpa | Feeding System: 10L Custom Storage Bucket + 2L Cleaning Tank |

| Ventilation Method: Built-in Filter Screen + Top Ventilation | Air Volume Requirement: 15m³/min |

| Number of Air Outlets: 1 | Power Supply: AC220V 50~60HZ |

| Communication Port: SMEMA Interface | Total Power: 3KW |

| Press Plate Device: Standard Configuration | Waste Liquid Recovery: Standard Configuration |

Optional features

| QR Code scanning | CCD visual positioning |

| Internal Circulation Heating System | Glue Shortage Alarm ( Float level transmitter or Weighing by Balance available) |

| Bottom PCB jig Return System | MES Access Permissions |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.