Inline Atmospheric Pressure Glue Potting Machine (HTG-450)

Advanced inline automatic potting machine designed for high-precision, large-volume potting. Featuring a PC-based control system, 3-axis servo motion, dynamic or static mixing, and continuous ratio feeding with 2 or 4 material tanks, it delivers stable, bubble-free, and drip-free dispensing for a wide range of PCB and electronic assembly applications. With automatic loading, program storage, anti-curing protection, vacuum degassing capability, and an integrated cleaning system, the HTG-450 offers reliable, fully automated, and highly flexible dispensing performance for modern production lines.

Inline Atmospheric Pressure Glue Potting Machine(HTG-450)

Introduction

• Control System:

Equipped with an industrial computer and motion control card, using a 21-inch display with mouse-and-keyboard operation. Programming is simple and user-friendly. The operating software is independently developed, making maintenance convenient. When editing dispensing programs, operators can select different mixing valves according to product requirements, and freely adjust Z-axis height based on PCB component height. All edited programs can be stored and recalled for different PCB boards. During spray operation without a workpiece, an anti-curing/dormant timer can be set. The machine will periodically perform a micro-purge to effectively prevent clogging of the dispenser gun and hose due to material drying.

• Machine Frame:

The base frame is welded from reinforced 60×60 mm square tubes with stress-relieved treatment, delivering excellent rigidity, hardness, and minimal thermal deformation. The working platform is precision-milled with a gantry milling machine to ensure the motion system operates on a stable and accurate platform. Other areas are covered with stainless steel to prevent conformal coating corrosion.The surfaces are finished with electrostatic powder coating for a refined appearance.

• Working Section:

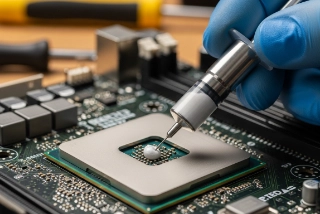

The X, Y, and Z axes motion platform consists of slide rails, lead screws, and servo motors. The Z axis is equipped with a static/dynamic mixing valve, and a brushless motor drives the stirring rod, with a stirring ratio from 1:1 to 1:10.

• Conveying Section:

Driven by a stepper motor with a double-speed chain conveyor, ensuring stable transport even with high-viscosity glue residue on the chain. The custom-developed aluminum conveyor structure is clean and aesthetically designed.

• Glue Supply System:

Provides automatic and precise ratio-mixing. Includes two or four SUS304 40L material tanks for continuous high-volume feeding. In a four-tank setup, the system automatically switches from A1/B1 to A2/B2 when levels reach the lower limit, enabling uninterrupted production. A and B materials are stored and supplied separately, supporting vacuum degassing. Vacuum tanks are placed on an independent platform with leveling feet for easy movement.

• Cleaning Function:

The machine features automatic cleaning. When switched to cleaning mode after stop, cleaning fluid from the pressure vessel is pushed through the valve and tubing, completing internal cleaning without manual disassembling the gun.

Features Summary

- 1. Supports dot, line, surface, arc, circle, and three-axis linkage functions to handle potting for irregular-shaped products.

- 2. Large-capacity storage without re-programming; The software features functions such as area array, translation, rotation operations, etc.

- 3. Adjustable glue volume,dispensing speed, dispensing time, and stop time; stable dispensing with no dripping.

- 4. Vacuum gauge with adjustable parameters; vacuum pump auto-stops when reaching upper limit.

- 5. Integrates mixing, dispensing, and trajectory potting with automatic loading/unloading.

- 6. On-demand metering enables mix-while-dispense, minimizing glue waste.

- 7. Built-in anti-curing timer; supports single-shot and continuous dispensing modes.

- 8. Independent control system unaffected by air pressure, preventing uneven flow, stringing, and bubbles.

- 9. Z-axis height adjustment accommodates components of various heights.

- 10. Material tanks equipped with level sensors and low-material alarms.

Equipment Parameters

| Model: HTG-450 | Equipment Color: Pure White |

| Power: 3.0KW | Potting Machine Main Body Dimensions: 1000x1200x1600mm |

| Power Supply: AC380V 50Hz | Operable Viscosity: <100000PCS |

| Static Interface: Standard Configuration | Control System: Industrial Computer + Display |

| Communication Port: SMEMA or IPC Hermes 9852 | Operating Software: Hetong Potting Machine Control Software V2.2 + Windows Operating System |

| Working Humidity: 20-90% | Driving Method: Servo Motor + Ball Screw |

| Mixing Ratio Accuracy: ±2% | Motion System: X, Y, Z Three Axes |

| Potting Accuracy: ±1% | Potting Stroke (XYZ): 450*450*100 mm |

| Cleaning Barrel: 1 Cleaning Barrel | Positioning Repeatability: ±0.02mm |

| Feeding System: 2 Feeding Barrels | Maximum Running Speed: XY Axis 800mm/s, Z Axis 100mm/s |

| Barrel Capacity: 40L | Number of Tracks: 1-section Transportation |

| Air Source: 0.4-0.6Mpa | Transportation Method: Speed Multiplier Chain |

| Vacuum Degree: No Vacuum | Transportation Direction: Left to Right and other optional |

| Number of Dispensing Nozzles After Mixing: 1 | Transportation Speed: 2-5m/min |

| Number of Mixing Valves: 1 pc and other optional | Transportation Height: 900±20mm |

| Board Passing Height: 100mm Above and Below the Track | Transportation Load Capacity: 15kg |

Optional features

| QR Code scanning | MES Access Permissions |

| Bottom PCB jig Return System | 4 glue storage supply tanks |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.