Offline potting station (HTG-E220)

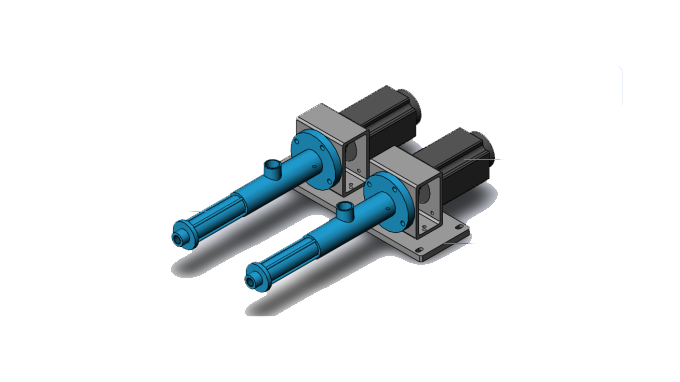

Designed as one of the working stations for your assembly line, semi-automatic function with a PLC-controlled dual-component potting system that uses gear and screw pumps for precise, stable, and bubble-free dispensing. With dual 40L tanks, adjustable parameters, and multi-path dispensing (dot/line/arc/3-axis), it delivers reliable, automated potting with minimal material waste.

Offline potting station(HTG-E220)

Introduction

- The system is controlled by a PLC and features a large, intuitive touch-screen interface for easy operation. A parameter-locking function prevents unauthorized or accidental modifications, guaranteeing consistent product quality.

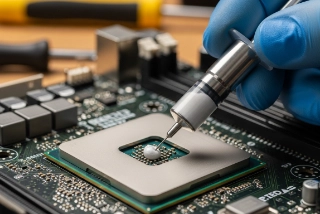

- Utilizes a gear pump and screw pump metering structure, enabling on-demand ratio control and real-time mixing and dispensing, significantly reducing material waste.

- Dual-tank design keeps A and B materials stored separately to prevent curing during long-term storage.

- The dispensing speed, dispensing time, and stop time can all be set by parameters, ensuring stable output without dripping.

- Supports dot, line, surface, arc, circle, and three-axis linkage functions to handle potting for irregularly shaped products.

- A independent control system ensures stable dispensing performance unaffected by air pressure, preventing uneven flow, wire drawing, and bubbles.

- Equipped with a liquid-level sensor for automatic low-material alarm.

- Optional features, such as glue stirring, heating, and vacuum-degassing functions support various potting processes.

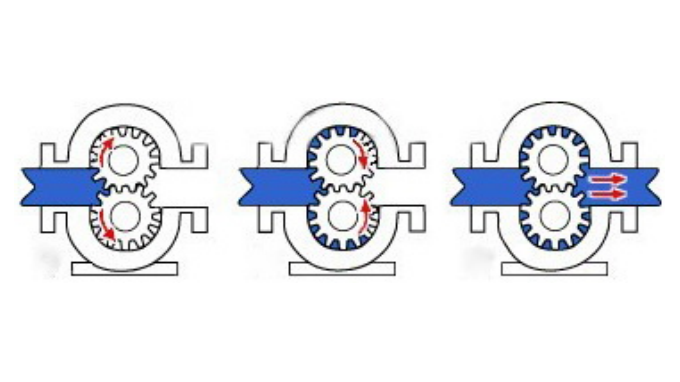

Pump Technology

1) Gear Pump diagram

- Stable pressure, high accuracy, unaffected by fluid viscosity/density variations.

- Compact structure, easy maintenance, and consistent flow proportional to pump speed.

2) Screw Pump diagram

- Works by forming sealed cavities between the screw and pump housing; as the screw rotates, material is pushed forward under uniform pressure.

- Features smooth, pulsation-free flow, high pressure, and high efficiency.

Equipment Parameters

| Model | HTG-E220 |

| Equipment Dimensions | 640mm×1385mm×1528mm |

| Operation Modes | Single-action, Automatic, Continuous-action |

| Control System | PLC + Touch Screen |

| Operation Method | Foot Switch / Start Switch |

| Glue Mixing Method | Dynamic and Static Mixing Valves Optional |

| Operable Viscosity | <100000 PCS |

| Anti-curing Time Setting | 0-100 Sec |

| Metering Pump | Gear Pump + Screw Pump |

| Mixing Ratio | 100: 100~100: 20 or 100: 20~100: 10 Adjustable |

| Dispensing Speed | 1g/sec~15g/sec or 5g/sec~30g/sec |

| Power Supply | AC220V 50HZ 2.0KW |

| Working Environment | Temperature: 0-40℃, Relative Humidity: 20-90% |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.