Full PCB Coverage Coating Machine(HTF-450A )

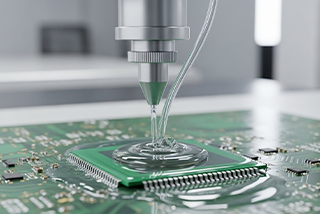

High-precision, fully automated conformal coating system designed for stable, accurate, and efficient PCB protection. Equipped with a servo-driven motion platform, chain-drive conveyor, adjustable atomizing spray valve, automatic soaking and cleaning systems, and UV inspection lighting, it ensures consistent coating quality, reliable operation, and easy maintenance

Full PCB Coverage Coating Machine(HTF-450A)

Introduction

1.Control System:

Equipped with an industrial computer and motion control card, operated via a 21-inch monitor with mouse and keyboard. Programming is simple and user-friendly.All programs can be stored and recalled for different PCB models. The system can automatically immerse the glue gun when no workpiece is present, preventing adhesive drying and clogging.

2.Machine Frame:

The frame is welded from thickened square tubes, ensuring strength and stability. The platform is made of stainless steel, offering high hardness, corrosion resistance, and easy cleaning. The surfaces are finished with electrostatic powder coating for a refined appearance.

3.Working Section:

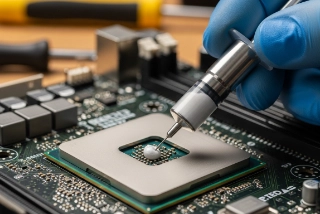

The Y-axis motion platform is made of a linear guide, lead screw, and servo motor. Compared with stepper motor systems, it provides more stable and precise motion control. The dispensing valve is equipped with a Japan-made SMC slide cylinder for smooth and accurate operation. The machine uses dispensing guns and high-precision atomizing spray valves with adjustable spray width. A fine-tuning pressure regulator ensures stable air pressure and consistent glue output, enabling cleaner and more precise edges.

4.Conveying System:

Driven by a 57 stepper motor, the machine maintains stable conveying even when high-viscosity adhesive sticks to the chain. The self-developed conveyor aluminum profile is elegant and practical. It uses a chain-drive transport method, and the conveyor width is manually adjusted through a gear-driven mechanism for higher accuracy, with a range of 50–450 mm. The chain is a 5 mm stainless-steel chain with extended pins and baffle plates.

- Glue Supply Unit:Equipped with a 5 L / 10 L pressure tank.

- Exhaust System:Uses a silent extractor fan that is compact, durable, and quiet.

- Soaking Unit:A custom-designed stainless-steel container provides easy glue-gun soaking and quick replacement.

- Lighting & Inspection:Comes with a built-in lighting system and UV inspection light source for convenient monitoring.

- Cleaning Function:The machine features an automatic cleaning function for easy maintenance

Equipment Parameters

| Model: HTF-450A | Power Supply: AC220V 50~60Hz |

| Exhaust Air Volume Requirement: 15m³/min | Overall Dimensions: 1000x1180x1806(mm) |

| Number of Exhaust Outlets: 1 | Weight: 450kg |

| Exhaust Mode: Built-in Filter + Top Exhaust | Control: Touch Screen + PLC |

| Air Pressure: 0.4Mpa | Transportation : Guide Rail + Chain |

| Feeding tank volume: 5L | Chain Type: 35B Stainless Steel Chain with Baffle and Extended Pin |

| Width Adjustment Speed: 250mm/min | Number of Tracks: 1-section |

| Width Adjustment Mode: Electric | Conveying Height: 900±20mm |

| PCB Edge Space: ≥5mm | Conveying Speed: 0-2400mm/min |

| Single Coating Width: 15-30mm | Conveying Direction: L→R Optional, R→L |

| Number of Valves: 1 | Maximum Transport Load: 20kg |

| Z-axis Configuration: Large Atomizing Valve | Driving Mode: Servo Motor + Ball Screw |

| Maximum Component Height: 80mm Above and Below Conveying Surface | Number of Axes: 1 |

| Coating Working Range: L450×W450mm | Repeatability precision: 0.02mm |

Optional features

| Glue Shortage Alarm ( Float level transmitter or Weighing by Balance available) | Bottom PCB jig Return System |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.