Inline Vacuum Potting Machine (HTD-550)

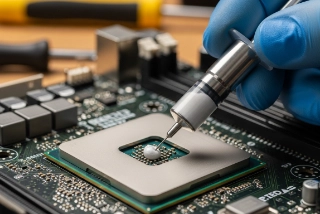

Features servo-driven 3-axis motion, automatic ratio mixing, vacuum defoaming, and continuous large-capacity supply. With dynamic/static mixing valves, screw-pump dispensing, huge program storage, and full automatic in/out feeding, it delivers stable, bubble-free, and highly consistent dispensing for complex PCB potting applications.

Inline Vacuum Potting Machine (HTD-550)

Introduction

• Control System:

Equipped with an industrial computer and motion control card, using a 21-inch display with mouse-and-keyboard operation. Programming is simple and user-friendly. The operating software is independently developed, making maintenance convenient. When editing dispensing programs, operators can select different mixing valves according to product requirements, and freely adjust Z-axis height based on PCB component height. All edited programs can be stored and recalled for different PCB boards. During spray operation without a workpiece, an anti-curing/dormant timer can be set. The machine will periodically perform a micro-purge to effectively prevent clogging of the dispenser gun and hose due to material drying.

• Machine Frame:

The base frame is welded from reinforced 60×60 mm square tubes with stress-relieved treatment, delivering excellent rigidity, hardness, and minimal thermal deformation. The working platform is precision-milled with a gantry milling machine to ensure the motion system operates on a stable and accurate platform. Other areas are covered with stainless steel to prevent conformal coating corrosion.The surfaces are finished with electrostatic powder coating for a refined appearance.

• Working Section:

The X, Y, and Z axes motion platform consists of slide rails, lead screws, and servo motors. The Z axis is equipped with a static/dynamic mixing valve, and a brushless motor drives the stirring rod, with a stirring ratio from 1:1 to 1:10.

• Conveying System:

Driven by a stepper motor with a 2.5 times speed chain conveyor, ensuring stable transport even with high-viscosity glue residue on the chain. The custom-developed aluminum conveyor structure is clean and aesthetically designed.

• Material Supply:

Provides automatic and precise ratio-mixing. Includes two or four SUS304 40L material tanks for continuous high-volume feeding. In a four-tank setup, the system automatically switches from A1/B1 to A2/B2 when levels reach the lower limit, enabling uninterrupted production. A and B materials are stored and supplied separately, supporting vacuum degassing. Vacuum tanks are placed on an independent platform with leveling feet for easy movement.

Features Summary

- 1. Supports dot, line, surface, arc, circle, and three-axis linkage functions to handle potting for irregular-shaped products.

- 2. Large-capacity storage without re-programming; The software features functions such as area array, translation, rotation operations, etc.

- 3. Adjustable glue volume,potting speed,potting time, and stop time; stable dispensing with no dripping.

- 4. Vacuum gauge with adjustable parameters; vacuum pump auto-stops when reaching upper limit.

- 5. Integrates mixing, dispensing, and trajectory potting with automatic loading/unloading.

- 6. On-demand metering enables mix-while-dispense, minimizing glue waste.

- 7. Built-in anti-curing timer; supports single-shot and continuous dispensing modes.

- 8. Independent control system unaffected by air pressure, preventing uneven flow, stringing, and bubbles.

- 9. Z-axis height adjustment accommodates components of various heights.

- 10. Material tanks equipped with level sensors and low-material alarms.

- 11. Optional German vacuum pump (165 m³/h)

Glue supply Tank Section (Two SUS304 40L Tanks)

- Automatic vacuum feeding with manual filling port and liquid level sight tube.

- Upper/lower level alarms

- Automatic vacuum defoaming after feeding

- Heating system adjustable from room temperature to 100°C

- Stirring motor for glue storage tanks prevents curing.

Equipment Parameters

| Model: HTC-550 | Transportation Direction:Left to Right and other optional |

| Power: 3.0KW | Potting Machine Main Body Dimensions: 1500x1200x1500mm |

| Power Supply: AC380V 50Hz | Operable Viscosity: <100000PCS |

| Static Interface: Standard Configuration | Control System: Industrial Computer + Display |

| Communication Port: SMEMA or IPC Hermes 9852 | Operating Software: Hetong Potting Machine Control Software + Windows System |

| Working Temperature: 0-40℃ | Driving Method: Servo Motor + Ball Screw |

| Working Humidity: 20-90% | Motion System: X, Y, Z Three Axes |

| Mixing Ratio Accuracy: ±2% | Potting Stroke (XYZ):550x550x100mm |

| Potting Accuracy: ±1% | Potting Speed:1g/sec~15g/sec or 5g/sec~30g/sec |

| Transportation Load Capacity: 5kg | Maximum Running Speed:XY Axis 800mm/s, Z Axis 100mm/s |

| Transportation Height: 900±20mm | Number of Tracks:1-section Transportation |

| Transportation Speed: 2-5m/min | Transportation Method:Speed Multiplier Chain |

| Positioning Repeatability:±0.02mm | Glue supply Tank volume: 40L or 70L and other optional |

Optional features

| QR Code scanning | MES Access Permissions |

| Bottom PCB jig Return System | 4 glue storage supply tanks |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.