Inline Five-Axes Dispensing Machine (HTD-450)

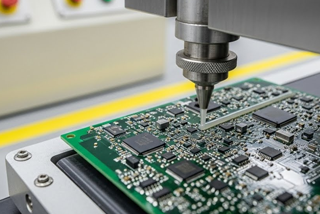

Inline 5-axes dispensing machine with CCD vision alignment, servo control, and stable automated glue supply.

Inline Five-Axes Dispensing Machine(HTD-450)

Introduction

- Control Section:

Equipped with an industrial computer and motion control board, operated via a 21-inch monitor with mouse and keyboard, simple programming and easy operation. The control software is independently developed for easy maintenance. When editing work programs, the operator can select different dispensing valves based on the spacing of components on the PCB, and adjust the valve height according to the component heights. The equipment can store all edited programs,the operator to call up the corresponding program for different PCBs. - Frame Section:

The base frame is welded from reinforced 60×60 mm square tubes with stress-relieved treatment, delivering excellent rigidity, hardness, and minimal thermal deformation. The working platform is milled flat by a gantry milling machine to ensure the motion system operates on a stable and precise platform.Other areas covered with stainless steel to prevent glue corrosion. The surfaces are treated with electrostatic powder coating for a fine appearance. - Working Section:

The X, Y, Z, U, and tilt five-axis motion platform consists of linear guides, ball screws, and servo motors. The XYZ axes use a self-developed sealed slide module to prevent glue material from attaching to the screw or guide rail. - Conveying Section:

The conveying system is driven by dual 57 stepper motors and chain transmission.The sliding rails are covered by protective strips. The self-developed conveyor aluminum profiles are both practical and aesthetic.The conveyor width is automatically adjusted by a stepper motor, which ensures high precision within an adjustable range of 50 to 450 mm. - Glue Supply System:

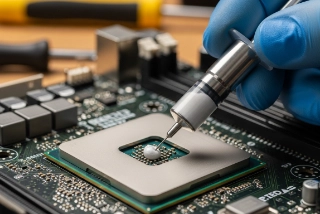

The system uses a servo pressing plate for glue supply. The pump consists of a servo motor with a stator and rotor,Equipped with a specialized screw pump controller, it enables rapid adjustment of glue output through rotational speed control. The repeatability of glue volume can achieve an accuracy of ±0.01cc. - Clamping System:

Upon detection of the PCB by an optical sensor,the machine initiates a clamping and lifting sequence to secure the board. This prevents any displacement during the dispensing process and enhances application accuracy. - Lighting and Inspection Section:

The equipment is equipped with an LED lighting system. - CCD Vision Positioning System:

The CCD camera captures PCB MARK points to determine the dispensing position. It can also be equipped with a barcode or QR code reader for code recognition.

Features summary

- 1. Industrial PC + Motion Control Card, Windows operating system,with audible/visual alarms and menu-guided interface.

- 2. Manual teaching programming method, simple and quick operation.

- 3. Driven by servo motor and ball screw.

- 4. X, Y, Z, U + tilt five-axis motion system.

- 5. Professional silicone pressure tank and servo press plate pump for stable glue output.

- 6. CCD vision positioning system — camera captures PCB MARK points for accurate dispensing.

- 7. LED lighting system.

- 8. Special aluminum alloy rail and stainless steel conveyor chain, single-section track.

- 9. Integrated steel motion platform ensures smooth operation.

- 10. Equipped with SMEMA or IPC Hermes 9852 interface for communication with other equipment.

Equipment Parameters

| Model: HTD-450 | Dimensions (LWH): 1000x1200x1766 mm |

| Machine Weight: About 500 kg | Control System: Industrial PC + Motion Control Card |

| Software: Hetong Dispensing Machine Control Software + Windows OS | Programming Method: Trajectory map programming; mouse and keyboard can speed up programming |

| Drive Type: Servo Motor + Ball Screw | Track Number: Single-section transport |

| Conveyor Height: 900 ± 20 mm | Conveyor Speed: 2–5 m/min |

| Transport Direction: L→R / R→L | Chain Type: 35B stainless steel chain with lugs and extended pins |

| Conveyor Max Load: Approx. 20 kg | Axis Number: 5 axes |

| Z-axis Valve Number: 1 | Z-axis Valve Configuration: High-pressure back suction valve |

| Rotation Angle: 0–180° | Tilt Angle: 0 to ±90° |

| Positioning Accuracy: ±0.02 mm | Repeat Positioning Accuracy: ±0.02 mm |

| X/Y Max Move Speed: 800 mm/s | Z Max Move Speed: 300 mm/s |

| X/Y Travel: 450*450 mm | Y-axis Stroke Range: 50–450 mm |

| Stroke Adjustment Method: Electric | Stroke Adjustment Speed: 250 mm/min |

| Max Component Height: ±100 mm from PCB surface | PCB Edge Clearance: ≥5 mm |

| Feeding System: 2600 ML | Air Source: 0.4–0.6 MPa |

| Power Supply: AC 220V, 50–60Hz | Total Power: 3 kW |

| Communication Port: SMEMA or IPC Hermes 9852 interface | Pressure Plate: Standard |

| Waste Liquid Recovery: Standard | Color: Pure White |

Optional features

| Scan code system | CCD visual positioning system |

| MES | UPS |

| Bottom PCB jig return system | Liquid low level alarm system |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.