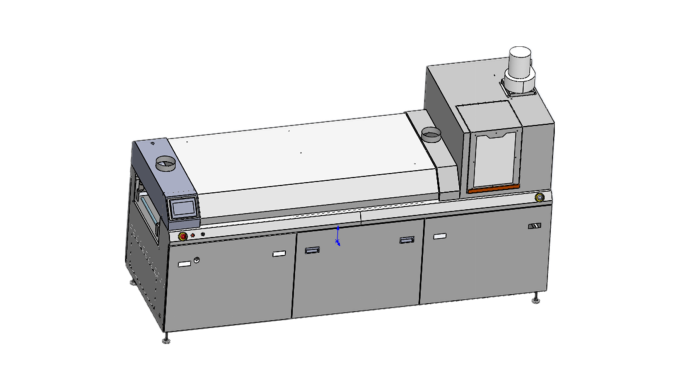

Infrared UV Integrated Curing Oven HT-IR2UV1

Features a durable precision frame, a 2-meter IR heating zone, and a 1-meter UV curing zone for fast and uniform curing. With Siemens PLC control, multi-zone PID temperature regulation, and comprehensive safety protection, it ensures stable and reliable operation. The stainless-steel chain transport system runs smoothly with automatic lubrication, while the electric lifting mechanism provides safe and easy access for maintenance. Compact, efficient, and versatile.

Infrared and UV Integrated Curing Oven HT-IR2UV1

Introduction

• Frame Section

- 1. The frame is welded with thickened square tubes and undergoes aging treatment, providing a solid and rigid structure.

- 2. The working surface is precision-milled with a gantry milling machine to ensure the motion system operates on a stable and accurate platform.

- 3. The surfaces are finished with electrostatic powder coating, resulting in a refined and high-quality appearance.

- 4. A specially designed space is reserved at the bottom, with a height of 350±20mm, allowing for the installation of Bottom PCB jig Return System.

• Control System

- 1. Controlled by Siemens PLC and a touch screen, offering simple operation.

- 2. Each heating zone uses PID temperature control to achieve precise multi-zone temperature management.

- 3. Equipped with a leakage protection circuit breaker to ensure the safety of operators and the control system.

- 4. Features a dual over-current protection system that cuts off power immediately when over-current occurs to ensure safety.

- 5. Includes over-temperature and low-temperature alarm systems to ensure safe heating and stable production.

- 6. Alarm method: automatic sound and light alarm.

• Heating System (Dual-Mode Curing System, default IR heating)

- 1. Two-stage heating design: 2 meter infrared curing zone + 1 meter UV curing zone.

- 2. The IR section uses infrared heating tubes, made of specially customized φ10mm fiberglass tubes.

- 3. Radiation shields positioned above IR tubes to maximize heat transfer to PCBs, enabling fast heating up to 150°C.

- 4. Multiple heating zones are independently temperature-controlled.

- 5. Each zone contains several infrared heating tubes arranged evenly.

- 6. The UV section uses a UV lamp, equipped with an independent controller.

- 7. Furnace chamber and liner made from special materials with thick insulation to minimize heat loss

• Transport System

- 1. Automatic chain lubrication ensures smooth product transportation.

- 2. Chain transmission is fully closed-loop controlled by the computer, allowing different product types to be processed simultaneously.

- 3. High-strength guide rails minimize thermal deformation, ensuring accuracy.

- 4. Track width adjustment is manual.

- 5. Transport method: stainless steel chain.

• Safe Upper Furnace Opening Mechanism

- 1. The upper-chamber of furnace is raised and lowered by an electric ball screw mechanism. This robust design ensures safe, reliable operation and prevents deformation.

- 2. Motorized lift equipped with lock-hold function, preventing sliding in case of power failure for maximum safety.

Equipment Parameters

| Model: HT-IR2UV1 | PCB Passing Height: ±100mm |

| Exhaust: 15m³/min at Maximum Power | External Dimension (LWH): 3000x1042x1618MM |

| Ventilation: External dia.150mm Ventilation Pipe | Weight: About350KG |

| Communication Port: Standard SMEMA or IPC Hermes 9852 | Control Mode: PLC + Touch Screen |

| Total Power: Approximately 15KW | Transportation Mode: Guide Rail + 35B Chain |

| Power Supply: 5-wire 3-phase 380V | Equipment Color: Computer White |

| Service Life of UV Curing Lamps: ≥1500h | Number of Tracks: One-stage Transportation |

| Power of Single UV Lamp in UV Curing Zone: 6kw | Track Length: 3 Meters |

| Height adjustment range of Lamp Group: 5-100mm | Conveying Height: 900±20mm |

| Irradiation Direction of UV Lamps:Top to Bottom | Rail Adjustable Width: 50~450mm |

| UV Curing Zone Length: 1 Meter | Width Adjustment Mode: Manual Adjustment |

| Power of Infrared Curing Zone: Approximately 4kw per Heating Zone | Overboard Height: 100mm for Upper and Lower Each |

| Number of Lamps in UV Curing Zone: Single Lamp Strip | Transportation Load Capacity: Approximately 20kg |

| Irradiation Direction of Infrared Lamp: Top to Bottom | Conveyor Belt Speed: 100~4000mm/min |

| Temperature Control Precision of Infrared Curing Zone: ±3℃ | Infrared Curing Length: 2 Meters |

| Temperature Control Range of Infrared Curing Zone: Room Temperature - 150℃ | Number of Infrared Heating Zones: 2 Heating Zones |

Standard features

| PCB Conveyor Speed Monitoring | Missing PCB detection during conveyor |

| PCB transfer error Monitoring | PCB Jam Alarm |

| PCB Request Interval Setting | PCB Stop Timeout Setting |

Optional features

| QR Code scanning | UPS |

| Bottom PCB jig Return System | MES Access Permissions |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.