Mobile Phone Screen Removal Machine HT-8090

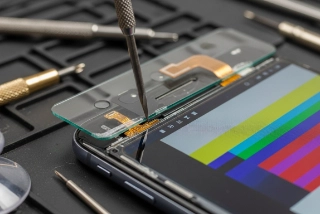

This machine separates the screen from the middle frame of mobile phone efficiently.

Mobile Phone Screen Removal Machine HT-8090

Introduction

• Equipment Parameters:

- 1. One Siemens PLC with temperature control module

- 2. Two stepper motors

- 3. 7-inch touchscreen for operation

- 4. One vacuum pump

- 5. One 600W heating tube + two 400W heating tubes

- 6. Two Omron digital vacuum gauges

- 7. Two vacuum relief valves and two pressure relief valves

• Working movements:

The equipment is controlled by a PLC and touchscreen, enabling adjustment of operation speed, temperature settings, reset functions, and other parameters. Two 57 stepper motors drive the lead screw at a constant speed to lift the separation mechanism smoothly. The vacuum pump performs the vacuum suction to hold the screen firmly, ensuring stable detachment.

• Workflow:

- 1.Set the machine to an appropriate temperature (typically 75–85°C) and allow it to reach stable heating. Place the phone in the preheating area for 3–5 minutes.

- 2.After preheating, Replace the phone into the separation area and press the start button.

- 3.The separation process begins. The vacuum pump draws a vacuum; once the required level is reached, the vacuum suction holds the screen firmly in a stationary position. The upper mechanism grips the phone's middle frame and is driven by a stepper motor to move at a preset speed. Thus, with the screen stationary and the middle frame moving, the screen is separated from the phone's frame.

- 4.When the upper mechanism reaches its working height, the screen is fully separated.

- 5.After completion, the machine resets and the buzzer beeps three times. Open up the upper mechanism and take out the screen and middle frame.

Equipment Parameters

| Model | HT-8090 |

| Working Cycle | 3min/Cycle |

| Heating Temperature | Room Temperature ~ 100℃ |

| Temperature Control | Siemens Temperature Control Module for Automatic Temperature Control, Precision ±1℃ |

| Product Range | Custom Molds of Any Size According to Customer Requirements |

| Product Fixing Method | Mold Fixing (Molds Customized to Customer Needs) |

| Mold Material and Precision | Custom Suction Cup |

| Machine Case Material | Cold Rolled Steel Plate |

| Moving Parts | Precision Guide Rail |

| Operating Speed | Stepless Speed Regulation |

| External Dimension | (Approx.) 900mm (L) × 640mm (W) × 1050mm (H) |

| Main Power Supply Specification | AC 220V±10%, 50Hz, 1.5kW |

| Machine Weight | 60kg |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.