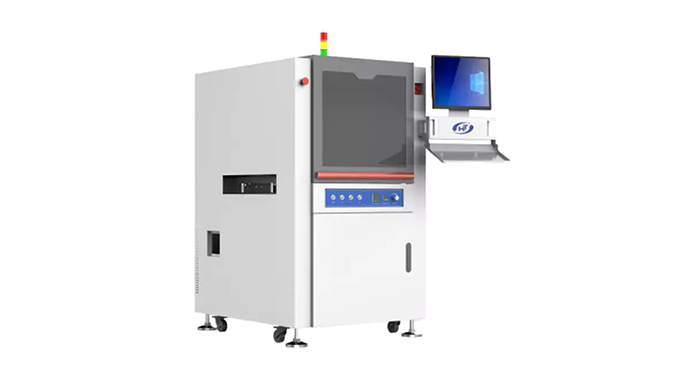

High-Speed Visual Dispensing Machine (HT800 series)

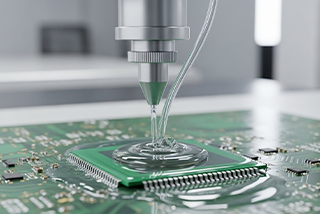

High-precision, high-speed dispensing and filling capabilities. Utilizing a jet-type metering system, it surpasses traditional contact dispensing methods by eliminating defects such as stringing, uneven glue volume, and component damage. This significantly improves both production efficiency and product quality. Equipped with powerful functional modules and flexible applications

High-Speed Visual Dispensing Machine (HT800 series)

Introduction

- 1.Control System:

Controlled by an industrial PC with control cards, operated via a 17-inch monitor with keyboard and mouse. The user-friendly software is self-developed for convenient programming and maintenance. The system allows Z-axis height adjustment according to height of PCB component and can store multiple programs for quick selection. - 2.Frame Structure:

The base frame is welded from thickened square steel tubing,features strength and rigidity With minimal thermal deformation, it ensures a stable and precise motion platform. The surface uses electrostatic powder coating, providing a refined appearance. - 3.Working Section:

The XYZ motion platform is driven by a combination of linear guide rails, ball screws, and servo motors. The XY axis modules are independently developed, ensuring smooth, accurate, and stable movement. - 4.Conveying System:

Driven by a 57-step motor, it maintains consistent transport even with high-viscosity adhesives. The self-developed aluminum conveyor structure is attractive and functional, featuring belt transmission and electrically adjustable width. - 5.Cleaning Function:

Equipped with an automatic cleaning system for easy maintenance and reduced downtime.

Features

- 1. Computer control with Windows OS, featuring audible and visual alarms with menu display.

- 2. CCD vision positioning system for automatic product recognition and precise alignment, replacing traditional mechanical positioning to achieve higher dispensing accuracy.

- 3. Supports offline programming with CAD file import and manual teaching modes.

- 4. With inline signal connection ports, SMEMA or IPC Hermes 9852 available.

- 5. Real-time dispensing volume monitoring.

- 6. Tolerant to PCB Warping

- 7. Modular design for flexible configuration.

- 8. Equipped with a piezoelectric jet valve for high-speed jet dispensing.

- 9. Adjustable dispensing point size.

- 10. Maximum viscosity up to 250,000 CPS

- 11. Uniform glue dots without stringing.

Equipment Parameters

| Model: HT-800 | Conveying Direction:L → R |

| Transport Load:5 kg | Transmission Motor Power: 57 series stepper motor |

| Conveying Height: 900±20mm | Control System: Industrial Computer + Motion Control Card |

| Number of Drive Axes: X, Y, Z (three axes) | Positioning Accuracy: ±0.02 mm |

| Repeat Positioning Accuracy: ±0.02 mm | X/Y Travel Range: 400 × 400 mm |

| Y-Axis Width Adjustment Range: 50–400 mm | Width Adjustment Method: Electric |

| Width Adjustment Speed: 250 mm/min | Max. X/Y Axis Speed: 1200 mm/s |

| Max. Z Axis Speed: 300 mm/s | Z-Axis Configuration: Dispensing valve + CCD vision positioning system |

| Z-Axis Valve Type: Piezoelectric jet valve | Number of Z-Axis Valves: 1 set (standard) |

| Dispensing Method: Jet type | Minimum Dispensing Volume: 0.015 mg |

| Material Supply tank: 30CC / 55CC / 100CC | Air Supply: 0.4–0.6 MPa |

| Power Supply: AC 220V, 50–60 Hz | Total Power: 2 kW |

| Communication Port: SMEMA or IPC Hermes 9852 | Static Elimination Interface: Standard |

| CCD Vision Positioning: Standard | Auto Cleaning: Standard |

| Nozzle Wiping: Standard | Overall Dimensions: 910*1140*1480(mm) |

Optional features

| PCB Preheating | Valve Rotation |

| Nozzle Heating | Fluid Path Heating |

| Dual Conveyor Line | Laser height measurement |

| Dual-Valve Adjustable Width | Micro Balance 0.1mg or 0.01mg precision |

| Pressurization System | UPS |

| Bottom PCB jig Return System | Upgrade to VERMES Piezo Valves |

| Upgrade to Pneumatic Jet Valve | Upgrade to Precision Screw Valve |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.