Long-Stroke Dispensing Machine(2000 Series)

Powerful modular functions and offers long-stroke applications

Long-Stroke Dispensing Machine(2000 Series)

Introduction

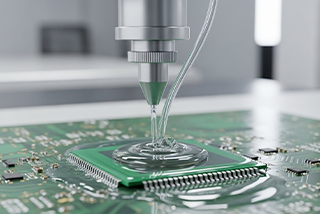

The HT-2000 Series Dispensing and Filling machine features precision, high-speed dispensing and filling performance. It adopts a jet-type quantitative feeding method, breaking through the limitations of traditional contact dispensing. This design effectively solves problems such as tailing, inconsistent glue volume, and potential damage to components or products.

The valve body can be equipped with either a piezoelectric jet valve or a rotary dispensing suck-back valve. Along the X-axis direction, products under 2000 mm can be dispensed in a single pass, while products longer than 2000 mm can be handled using a two-stage dispensing process.

The HT-2000 Series is equipped with powerful modular functions and offers flexible applications — making it the preferred choice for precision dispensing and filling.

Features

- 1. The machine frame is made of thickened square tubes with stress-relieved treatment.

- 2. High-speed, reliable, and stable transmission and control system. X, Y, and Z axes all adopt Panasonic servo motors, high-precision ball screws, and linear guide rails.

- 3. The control system uses an industrial PC with a motion control card and display. It runs on Windows 7, featuring a patented high-speed dispensing control system with real-time trajectory and parameter display, as well as audible and visual fault alarms with menu display.

- 4. Supports offline programming, including CAD file import and manual teaching modes.

- 5. Equipped with automatic online signal connection ports.

- 6. Inline conveyor system capable of communication with other equipment.

- 7. CCD precision visual positioning system.

- 8. Tolerant to PCB warpage

- 9. Modular design for flexible configuration..

- 10. SMEMA or IPC Hermes 9852 interface for connection to upstream/downstream equipment

- 11. The piezoelectric jet valve enables non-contact, high-speed dispensing.

- 12. Dispense size can be freely adjusted.

- 13. Supports materials with viscosity up to 250,000 CPS.

- 14. Uniform dot shape with no tailing.

- 15. The rotary suck-back valve supports contact dispensing.

- 16. Can perform vertical or angled rotary dispensing.

- 17. Ensures even discharge, clean break-off, and no stringing.

- 18. Equipped with an automatic cleaning function.

Equipment Parameters

| Model: HT-2000 | Overall Size: 2600×1180×1590mm |

| Total Weight: 1200kg | Control Method: Motion Control Card + Industrial PC |

| Control Axes: X, Y, Z Axes | XYZ Drive System: Servo Motor + Ball Screw |

| Positioning Accuracy: ±0.02mm | Repeat Positioning Accuracy: ±0.02mm |

| Software Control System: Windows 7 OS + Hetong Dispensing Software V2.2 | Programming Mode: Offline or Online Vision Programming |

| Conveying System: 86 Stepper Motor + Conveyor Belt | Track Quantity: Single Track |

| Conveying Power: One-Section Drive | Conveying Height: 900±20mm |

| Maximum Operating Speed: 1500mm/s | Load Capacity: 10kg/㎡ |

| Vision Positioning System: CCD Vision Alignment | Z-axis Valve Configuration: Piezoelectric Jet Valve / Rotary Back-suction Dispensing Valve / Others |

| Valve Quantity: 1 / 2 | Dispensing Length: Max 2000mm per segment |

| Dispensing Area (XYZ): X=2000mm, Y=400mm, Z=50mm | Rail Width Adjustment Range: 50–400mm |

| Width Adjustment: Electric Adjustment | Input Voltage: 220V 50–60Hz |

| Input Air Pressure: 5–6kg/cm² | Total Power: 3.5kW |

| Communication Port: SMEMA or IPC Hermes 9852 | Cleaning System: Automatic Cleaning |

Optional features

| Dual valves | Dual-Valve Adjustable Width |

| Valve Rotation | MES Access Permissions |

| Dual Conveyor Line | Laser height measurement |

| Heating | Micro Balance 0.1mg or 0.01mg precision |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.