AOI-Enabled Conformal Coating Machine (HTF-VCA450)

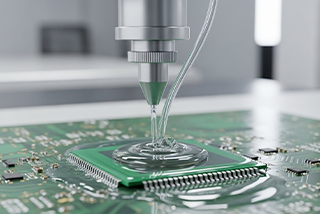

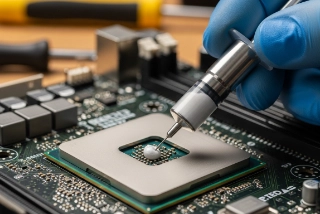

High-performance industrial PC and a 3-axis servo motion platform, combined with a professional optical inspection module for accurate detection of various conformal-coating defects. With an auto-adjust conveyor, rigid steel frame, dual LED/UV lighting, and MES connectivity, it delivers high precision, stability, and intelligent coating inspection.

AOI-Enabled Conformal Coating Machine (HTF-VCA450)

Introduction

- Control Section:

Equipped with a high-configuration industrial computer and a reinforced high-performance motion control card. The display adopts a 21-inch LCD monitor, with mouse and keyboard for operation. The system runs on Windows 10. The software control system is independently developed, featuring simple programming, easy operation, and support for polygon programming mode, allowing quick definition of irregular coating areas. It supports one-click search for coating boundaries and glue inspection at any position on the entire board. The program is stable and supports multi-machine copying. - Machine Frame:

The base frame is welded from reinforced 60×60 mm square tubes with stress-relieved treatment, delivering excellent rigidity, hardness, and minimal thermal deformation. The working platform is precision-milled with a gantry milling machine to ensure the motion system operates on a stable and accurate platform. The surfaces are finished with electrostatic powder coating for a refined appearance. - Working Section:

The X, Y, and Z three-axis motion platform is composed of linear guides, ball screws, and servo motors, providing stable and high-precision motion control.

The Z-axis optical inspection system uses a professional color industrial camera and a telecentric industrial lens, effectively reducing shadowing caused by high components on PCB. It can accurately identify various coating defects on PCB boards after conformal coating, including over-coating, under-coating, splashing, bubbles, glue width issues, etc., maximizing the yield rate of the coating and curing production line. - Conveyor Section:

The conveyor is driven by a stepper motor. The self-developed aluminum conveyor rail is convenient and visually appealing. The transmission method is chain-drive, and conveyor width is automatically adjusted by a stepper motor with higher precision. Adjustment range: 50–450 mm.

The chain adopts 35B stainless steel chain with extended pins and baffles. - Clamping Device:

Upon PCB entry, sensors trigger automatic stop, clamping, and top-holding to keep the PCB firmly fixed, preventing shifting during coating and ensuring accurate positioning. - Lighting Inspection:

Equipped with LED lighting an LED UV light source. Operators can switch between them to inspect conformal-coating coverage efficiently. - Information Traceability:

Reserved MES interface. Support customer MES communication protocols and supports automatic statistical SPC analysis and SPC alarms.

Feature Summary

- Adopt industrial computer + motion control card, Windows 10 64-bit operating system, with audible/visual fault alarm and menu display.

- Programming uses manual teaching mode, simple and fast operation.

- Driven by servo motor + ball screw.

- X, Y, Z three-axis motion (standard configuration).

- Operating accuracy of 0.02 mm, capable of automatic error compensation.

- Special aluminum alloy rail and stainless-steel conveyor chain, single-section guide rail.

- Integrated steel motion platform ensures stable operation.

- Equipped with SMEMA or IPC Hermes 9852 interface for communication with other equipment.

Equipment Parameters

| Model:HTF-VCA450 | Conveying Motor Power:57 Series Stepper Motor |

| External Dimensions:1050×1275×1991(mm) | Axis Number:X, Y, Z |

| Machine Weight:450kg | Positioning Accuracy:±0.02mm |

| Control System:Industrial Computer + Motion Control Card | Repeat Positioning Accuracy:±0.02mm |

| Total power: 2.4 KW | Max Speed (X/Y Axis):800mm/sec |

| Programming Method:Trajectory diagram available;

mouse/keyboard speeds up programming; offline CAD import supported |

Max Speed (Z Axis):300mm/sec |

| Driving Method:Servo Motor + Ball Screw | X/Y Axis Stroke:450×450mm |

| Number of Tracks:1-section Transportation | Y Axis Amplitude Range:50~450mm |

| Conveying Height:900±20mm | Amplitude Adjustment:Electric |

| Conveying Speed:2-5m/min | Adjustment Speed:250mm/min |

| Press Plate Device:Standard Configuration | Max Component Height:100mm (above/below conveying surface) |

| Chain Type:35B Stainless Steel Chain (with Blocker & Extended Pin) | PCB Thickness:0.5~4.0mm |

| Max Transportation Load:20kg | PCB Edge Space:≥5mm |

Automated Optical Inspection details

| Camera | 5MP□ 12MP□ 20MP□ Other□ |

| Field of view resolution | custom made |

| Camera lens | Industrial Telecentric Lens |

| Light source | UV + W Light Source / UV + RGBW Light Source |

| High-speed imaging | 0.2-0.25s/FOV |

| Thickness measurement method | Excluding R

Single-sided thickness measurement £ Double-sided thickness measurement£ |

| Thickness measurement range | 21μm-600μm |

| Thickness measurement repeatability | 3-5μm |

| Scannable & Recognizable by Camera | 1D code, QR code, OCR |

| Other function | Automated Statistical Process Control (SPC) and Maintenance Station |

| Deep learning | AI Bubble Detection and Localization with mixed recognition of numbers and English letters |

| Integrated Vision and Control | Deep integration of vision and motion control.

|

| Mutual Stress Testing between Programs | Support |

| Mixed PCB Production Support: | Automatically identifies the PCB's front and back side to invoke different processing programs. |

| Box-Selection for Coating Areas | Supports polygons and quickly defining irregular areas |

| One-Click Coating Boundary Detection | Support |

| AI box-selection automatic recognition | Box-Selection a component of a specific type with a single click, Set for inspection, can automatically search for all components of the same type across the entire PCB. |

| Glue width detection | Supports S-shaped or arbitrary path measurement |

| Excessive glue

detection |

Support |

| Insufficient Glue

detection |

Support |

| Splash&scatter Defect

detection |

Support |

| Bubble detection | Support Bubble detection>0.05mm |

| Foreign object detection | Support |

| Orange Peel Pattern Detection | Support |

| Detection of Missing, Damaged, or Displaced Components | Support |

Optional features

| QR Code scanning | UPS |

| Bottom PCB jig Return System | MES Access Permissions |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.