2-Meter Infrared Curing Oven (HT-IR2000 )

2-meter infrared curing oven featuring precise multi-zone PID temperature control, fast IR heating up to 150°C, stable chain-drive transport, and a safe motorized lifting furnace design. With efficient insulation, it delivers reliable, uniform, and energy-saving curing for PCB manufacturing.

2-Meter Infrared Curing Oven(HT-IR2000)

Introduction

• Control System:

- 1. Siemens PLC with touchscreen for simple, intuitive operation

- 2. PID temperature control for each heating zone, ensuring precise multi-zone temperature regulation

- 3. Equipped with leakage protection switch for operator and system safety

- 4. Dual over-current protection to cut power immediately when abnormal current occurs

- 5. Over-temperature and low-temperature alarm system to ensure safe heating and stable production

- 6. Audible and visual alarm function

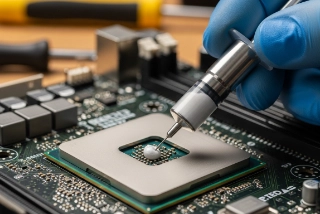

• Heating System:

- 1. Infrared heating with customized φ10 mm fiberglass IR tubes

- 2. Radiation shields positioned above IR tubes to maximize heat transfer to PCBs, enabling fast heating up to 150°C

- 3. Two independent heating zones with separate temperature control

- 4. Each zone equipped with seven evenly arranged infrared emitters

- 5. Furnace chamber and liner made from special materials with thick insulation to minimize heat loss

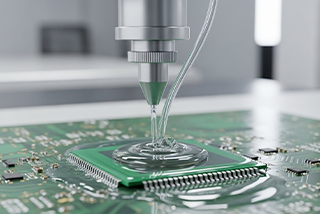

• Transport System:

- 1. Chain conveyor with fully closed-loop computerized control, suitable for various PCB types

- 2. High-strength guide rails with minimal thermal deformation for stable accuracy

- 3. Manual width adjustment

- 4. Transport mode: chain drive

• Safe Upper-Chamber Opening Design:

- 1. The upper-chamber of furnace is raised and lowered by an electric ball screw mechanism. This robust design ensures safe, reliable operation and prevents deformation.

- 2. Motorized lift equipped with lock-hold function, preventing sliding in case of power failure for maximum safety.

• High Efficiency & Energy Saving:

- Low startup and average power consumption

Equipment Parameters

| Model | HT-IR2000 |

| Weight | About 250KG |

| Control Mode | PLC + Touch Screen |

| Transportation Mode | Stepper Motor + 35B Chain |

| PCB Conveying Height | 900±20mm |

| Rail Adjustable Width | 50~450mm |

| PCB Passing Height | ±100mm |

| Conveying Direction | Left → Right |

| Conveyor Speed | 30~2000mm/min |

| Transportation Load Capacity | 20kg/m |

| Temperature Control Range | Room Temperature ~ 150℃ |

| Temperature Control Precision | ±3 |

| Heating Zones | 2 Heating Zones |

| Heating Time | Approx. 20min |

| Power Supply | 5-wire 3-phase 380V |

| Power | Approx 9KW |

| Communication Port | SMEMA or IPC Hermes 9852 |

| External Dimension (LxWxH) | 2000x960x1250MM |

Application Range

Our Advantages

Quality

We have 13 quality engineers to ensure product reliability, safety, and compliance with industry standards.

Service

After-sales teams distributed in multiple locations can provide overseas after-sales services.

R & D

A research and development team of 21 members continuously drives innovation.

Install

We provide technical support, installation guidance, and other services to address your concerns.